A Chinese team has shown that last autumn’s corn stalks can be transformed into a palm-oil-like fat suitable for aviation biofuel or cosmetics without the energy-guzzling steps that have kept lignocellulosic biorefineries on the drawing board.

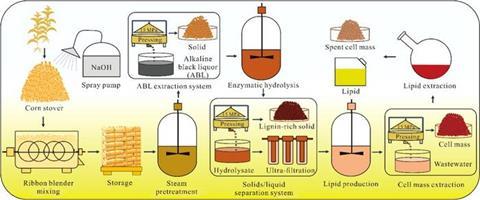

Researchers from the Dalian Institute of Chemical Physics and Dalian University of Technology filled a 1,000 L stainless-steel fermenter with corn stover that had been sprayed with 6 % NaOH, sealed in plastic bags at ambient temperature for 80 days, steamed for one hour and then squeezed like cider to remove black liquor.

READ MORE: Wheat straw and muncipal waste - how next generation biofuels can save the world

READ MORE: Understanding plant-microbe interactions to improve the cultivation of biofuels

The resulting amber hydrolysate fed the red yeast Rhodosporidium toruloides for five days, producing 10.6 g L⁻¹ intracellular lipids—66 % of the cell dry weight—while using only one-third of the water demanded by conventional 5 % solids processes.

The work, now published in the Journal of Bioresources and Bioproducts, is one of only a handful of pilot-scale demonstrations of microbial lipids from true agricultural waste.

“We wanted to prove that high-solids loading is not just a laboratory curiosity,” says corresponding author Zongbao K. Zhao. “By letting the alkali do the chemistry during storage, we avoid the high-temperature, high-pressure reactors that scare investors.”

Alkaline storage trick

Central to the success is the ’alkaline storage’ trick. Dissolving 60 g NaOH per kilogram of 20 %-moist stover creates a pH > 13 barrier that shuts out fungi and most bacteria, allowing the biomass to sit in ventilated bags for months without spoilage. During this time the lignin–carbohydrate network loosens: ester bonds break, hemicellulose swells and cellulose fibres become more accessible.

When the team opened the bags they added only water, steamed the mass at 121 °C for 60 minutes and pressed it in a simple cloth filter-press at 15 MPa. This removed 330 L of dark alkaline liquor—two-thirds of the original moisture—taking with it phenolics, ash and organic acids that would otherwise poison yeast.

Enzymatic hydrolysis of the squeezed cake released 72.7 g L⁻¹ total reducing sugars, 93.6 % of the theoretical yield, without the extra detoxification steps normally required.

Three-step seed train

The hydrolysate was fed to a three-step seed train culminating in a 500 L working volume inside the 1 000 L reactor. Over 120 h the yeast consumed 36.4 kg of sugar, generating 8 kg of biomass that contained 5.3 kg of lipid—a yield of 0.194 g g⁻¹ sugar, identical to the best small-flask results.

Oleic acid dominated the fatty-acid profile (57 %), followed by palmitic (22 %) and stearic (12 %), a spectrum that mirrors palm oil and is readily converted to biodiesel or aviation paraffin via hydrotreatment.

Mass-balance analysis shows 89.6 % of the stalk cellulose and 95.5 % of the hemicellulose ended up as fermentable sugar, while one-fifth of the lignin dissolved in the alkaline liquor, leaving the rest in a filter cake that could be burned for process heat.

Energy monster

Perhaps most importantly, the process eliminates centrifugation. “At 20 % solids a centrifuge becomes an energy monster,” Zhao notes. “Squeezing gives us the same solid-liquid split with a tenth of the power.”

The team calculates that replacing centrifuges with filter-press operations cuts electricity demand by 70 % and capital cost by 40 %, pushing the minimum selling price of the yeast oil below USD 1 200 per tonne—competitive with palm oil when carbon credits are included.

The researchers are now negotiating with a corn-processing company to run a 10,000 L campaign next season, aiming to integrate the lipid stream with existing ethanol plants. If successful, the route could turn millions of tonnes of stover now left on fields—or worse, burned—into renewable oleochemicals while returning minerals-rich press cake to the soil.

Topics

- agricultural waste

- Agriculture

- alkaline storage

- Asia & Oceania

- biorefineries

- Climate Action

- corn stover

- Dalian Institute of Chemical Physics

- Dalian University of Technology

- Economic Equality

- Food Security

- Fungi

- Healthy Land

- Industrial Microbiology

- microbial lipids

- Personal Care Product & Cosmetics

- Research News

- Rhodosporidium toruloides

- Waste Management

- Zongbao K. Zhao

No comments yet