For decades, microbial detection and quantification have been a persistent bottleneck across industries. Despite the essential role of microbiological quality control in pharmaceuticals, cosmetics, water, food, and environmental safety, the field has long relied on slow, manual, and often imprecise methods. Over the past forty years, many have attempted to bring innovation to this space. Their limited success doesn’t reflect a lack of need, but rather the complexity and significance of the challenge.

Today, the landscape is shifting. Regulatory expectations are evolving, technology has reached new heights, and the demand for robust, real-time data is changing how industries operate. At Spore.Bio, we believe the conditions have finally aligned. This is the moment to deliver a new generation of rapid, reliable, and compliant microbial detection.

The burden of the status quo

The limitations of traditional methods are no longer acceptable. Standard culture-based techniques often require up to fourteen days of incubation before results are available. This delay affects decision-making in critical sectors like pharmaceutical production, water safety, and food processing. These methods are not only slow but also labor-intensive, vulnerable to contamination, and incapable of detecting certain microbial forms such as viable but non-culturable pathogens. The result is frequent diagnostic delays, incomplete data, and operational inefficiencies that ripple through entire production systems.

The consequences are considerable. In pharmaceuticals, delayed microbial detection can halt manufacturing, increase production costs, and lead to regulatory non-compliance. In food and water safety, delays or false negatives can result in contamination events, product recalls, and risks to public health. Across sectors, the status quo carries heavy economic and reputational costs. There is no question that faster, more sensitive, and more reliable methods are urgently needed. This is not simply a matter of efficiency; it is foundational to safety and business continuity.

Why now? The perfect momentum

We are now at a point where meaningful transformation is finally possible. Regulatory bodies in Europe, the United States, and beyond are signaling openness to new approaches. The European Pharmacopoeia Commission has adopted revised texts related to pharmaceutical waters, explicitly welcoming alternative, rapid microbiological methods. Public consultations on the broader adoption of such methods are underway, indicating growing support from authorities like the EDQM. At the same time, the European Commission is tightening directives for natural mineral waters, placing new emphasis on microbial purity. In food safety as well, regulatory frameworks are becoming more stringent, with updated criteria driving demand for more responsive detection tools.

This regulatory evolution is not just a matter of compliance. It reflects a growing recognition that legacy methods can no longer keep up with the pace of modern industry. It also demonstrates that innovation in this space is not only welcome: it is necessary.

Simultaneously, technological progress has reached a point where long-held ambitions for faster, automated microbial detection can now be realized. The past decade has brought major advances in imaging, automation, and artificial intelligence. High-resolution microscopy and digital imaging systems now enable single-cell visualization and quantification. Machine learning models trained on vast image datasets can classify microbial cells with accuracy exceeding 90 percent in clinical studies. These systems can process thousands of samples daily with minimal human input. Deep learning models capable of analyzing complex biological signatures such as Raman spectra or genomic sequences are delivering results in minutes. What once required highly trained specialists and dedicated labs is now achievable on-site with compact, automated platforms. Costs for high-performance optics, sensors, and computing power have dropped dramatically, making these technologies broadly accessible.

Laboratory automation, coupled with AI and robotics, is transforming how data is collected, interpreted, and used. Real-time capture and analysis are no longer futuristic goals. The lab is no longer a bottleneck; it is becoming a source of competitive advantage.

At the same time, the importance of data integrity has never been higher. In highly regulated sectors, data is trust. Regulators around the world have increased scrutiny on data handling practices, particularly in pharmaceutical microbiology. Traditional methods, which often rely on paper records, manual data entry, and subjective interpretation, are inherently prone to error and manipulation. AI-powered systems offer a fundamentally stronger alternative. Automated capture, algorithmic analysis, and secure digital records ensure that every data point is timestamped, traceable, and tamper-evident. These systems not only meet the highest standards for data integrity but also enable real-time monitoring, deviation detection, and seamless integration into quality systems. They support a move from reactive compliance to proactive quality assurance.

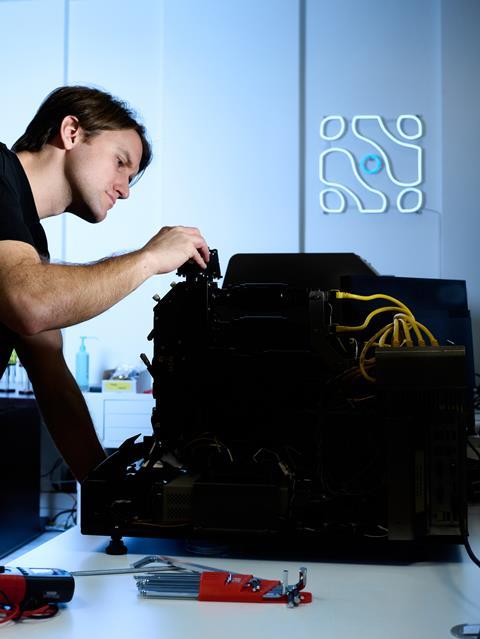

Spore.Bio: built for this moment

At Spore.Bio, we are not simply reacting to these changes; we are helping drive them. We have built a microbial detection platform that brings advanced AI and optical technologies out of the lab and into real production environments. Our partners are already seeing the benefits: real-time microbial monitoring, accelerated release times, and improved compliance, all integrated into their daily operations. This is not a vision for the future; it is happening now.

Our approach is defined not only by innovation but by execution. We have developed a system that delivers results in minutes with precision that meets or exceeds regulatory requirements. By combining proprietary AI algorithms, advanced imaging, and secure digital workflows, we ensure that every result is robust, reproducible, and ready for inspection. We are not automating outdated processes. We are redefining what is possible. We are giving teams the ability to see the invisible and act on it with confidence and speed. For the first time, microbial quality control can keep up with the pace of modern manufacturing. There is no longer a need to choose between speed and accuracy. The competitive advantage of real-time, AI-powered microbial detection is now clear, measurable, and transformative.

At Spore.Bio, our mission is to make this new standard of microbiology accessible to every organization that depends on it. We are already working with leaders across industries to make microbial detection faster, safer, and smarter. After decades of inertia and incremental progress, the convergence of regulatory, technological, and operational change has opened a true window of opportunity.

We are proud to stand at the forefront of this revolution. And we invite regulators, industry partners, and innovators to join us in building the future of microbial quality where accuracy, speed, and integrity are not trade-offs, but expectations.

No comments yet