A technological shift is transforming the biomanufacturing landscape. While demand for better, sustainable, novel, and bio-based products is surging, microbial processes at the heart of this transformation are still hindered by slow, expensive, and labor-intensive experimentation. Today, robotics and AI are no longer futuristic concepts, they are reshaping microbiology labs, enabling scientists to tackle once-intractable problems and accelerate innovation.

Automation enters the microbiology lab

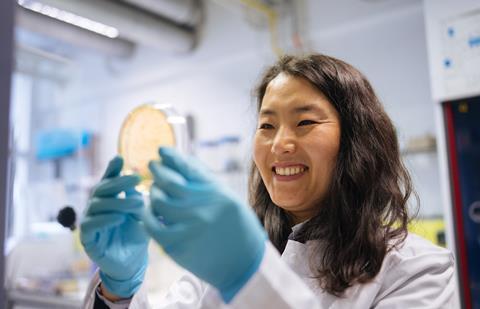

Dong Zhao steps into Differential Bio’s lab on the Technical University of Munich’s biotech campus in Weihenstephan, just outside Munich, home to the world’s oldest brewery and a renowned hub of fermentation research. Unlike traditional microbiology labs, Differential Bio’s space hums with the orchestrated movements of robotic arms and the subtle vibration of automated liquid handlers dispensing into microtiter plates. Rows of tiny wells blink under LED lights, each containing precisely formulated media designed not by hand, but by an algorithm. For Dong, CSO and Co-Founder of Differential Bio, the future of bioprocess optimization is already here.

“When I think back to how we as scientists used to run experiments - a couple of variables at a time, waiting days or weeks for results - it feels like another era,” Dong contemplates, glancing at the screen as her experiments unfold in real time. In recent years, this integration of robotics and AI has fundamentally reshaped how scientists approach microbial fermentation.

The bottleneck of traditional bioprocess development

Just a few years ago, creating an optimal microbial growth environment required significant manual labor, extensive trial and error, and months of iterative experimentation. Traditional bioprocess development relied on intuition and experience, often yielding inconsistent results and limiting the range of process parameters that could be explored. But at Differential Bio, a Biotech startup founded in 2023, Dong and her colleagues leverage robotics and AI to transform a laborious process into a streamlined, high-throughput operation.

The implications for microbiology and biomanufacturing are profound. Bioproducts, ranging from probiotics for gut health to sustainable biofuels for cargo ships, are increasingly essential for modern life. Yet despite their promise, microbial bioprocesses remain costly and time-intensive to optimize. The complexity of microbial metabolism and growth means traditional optimization often involves exhaustive experimentation, significant resource investment, and uncertain outcomes.

“Developing a bio-based product used to take 5–10 years and cost hundreds of millions of euros,” explains Dong. This reality often leads promising innovations to stall or fail in the commercial “valley of death”, the critical stage between laboratory success and market-ready product.

From data to discovery: the power of predictive AI

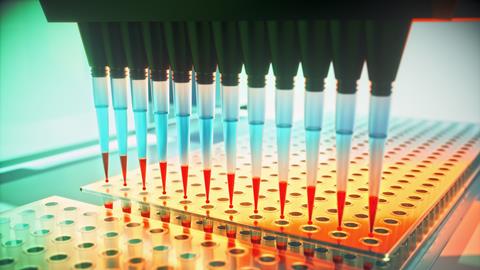

To address this bottleneck, the team behind Differential Bio develops a three-step approach combining robotic automation, AI-driven predictive modeling, and virtual experimentation. At the first tier, Differential Bio’s robotic infrastructure generates high-quality data at a scale that traditional methods can’t match. Automation ensures reproducibility and accuracy, enabling the team to run thousands of precisely controlled experiments simultaneously at a fraction of the usual cost.

This rich dataset feeds directly into the second tier: advanced AI modeling. Differential Bio employs machine learning algorithms to decode how microbes respond under varying conditions such as nutrient composition, pH or temperature.

“We don’t just model data; we teach our algorithms to understand microbial behavior,” emphasizes Martin Patz, the CTO and Co-founder of Differential Bio. “By learning the nonlinear relationships between media composition and microbial performance, our models can predict outcomes and reduce much of the trial-and-error.”

A user-friendly software platform lets researchers interact directly with Differential Bio’s predictive models. Researchers can conduct thousands of virtual experiments, rapidly exploring diverse conditions and pinpointing optimal solutions without physically performing each experiment. These in-silico results can then be validated in the lab and implemented into real-world bioprocesses.

The value of this approach is vividly demonstrated in a recent collaboration with a leading probiotics manufacturer for pet food applications. By applying their AI-driven platform, Differential Bio achieved high double-digit percentage-level biomass yield improvements and significant reductions in media costs for the client’s probiotic strain. Such breakthroughs underscore the transformative potential of AI-powered bioprocess optimization.

Expanding the frontier of bioprocess development

Yet, the promise of robotic and AI-driven biomanufacturing extends far beyond incremental productivity gains. Differential Bio’s approach represents a fundamental shift in how microbiologists design and optimize bioprocesses. By automating routine tasks, scientists like Dong can dramatically increase their throughput and dive deeper into the underlying biology.

“We’re no longer confined by the limitations of manual experimentation,” Dong reflects. “Instead of just collecting data, we can focus on insights and innovation.” And this is only the beginning. By tapping into the scaling laws of robotics, we move closer to unlocking the full potential of biomanufacturing.

Differential Bio’s vision isn’t merely to streamline existing processes, but to radically expand what is achievable. Traditionally, microbial optimization strategies focused on minor improvements within constrained experimental parameters. Differential Bio’s high-throughput approach increases the accessible search space for bioprocess configurations by a factor of 31. By systematically and efficiently navigating this vast experimental landscape, Differential Bio empowers researchers to uncover novel conditions and strategies previously unthinkable.

Imagine developing entirely new growth media or conditions that not only enhance yields and improve product quality, but also enable microbes to thrive in industrial environments where they previously couldn’t survive,” Dong explains. Such discoveries are increasingly plausible, thanks to the combination of robotics and predictive AI modeling.

Moreover, Differential Bio integrates multi-omics data to strengthen their models’ predictive accuracy. By blending these rich biological datasets with machine learning, Differential Bio can identify metabolic bottlenecks and mechanistic insights, moving beyond simple correlations towards genuine biological understanding.

This hybrid modeling approach, combining data-driven AI with biologically informed constraints such as flux balance analysis and kinetic modeling, allows Differential Bio’s predictions to be both interpretable and transferable across different strains and production scenarios.

Towards the future

The broader implications for the industry are significant. The global bioeconomy is estimated to reach $4 trillion, driven by demand for sustainable and bio-based products. Yet, biomanufacturing remains hindered by substantial upfront investment and prolonged development timelines. Differential Bio’s innovative approach dramatically reduces both time and financial barriers, enabling faster commercialization and reducing risks for bio-based innovations.

The initial target markets for Differential Bio are precision fermentation applications where cultured cells directly form or constitute key ingredients, including probiotics, biofuels, dairy alternatives, and food additives. Metabolite prediction unlocks access for Differential Bio to high-value synthetic biology applications, ranging from industrial biotechnology to pharmaceutical innovation.

Back in the lab, Dong monitors the afternoon’s automated experiments, confident that the next breakthrough is not a question of “if” but “when.” For Differential Bio, harnessing AI and robotics isn’t just about efficiency; it’s about fundamentally transforming microbiology into a realm of possibility previously limited by human capability.

Indeed, for microbiologists everywhere, Differential Bio’s journey suggests a future where the limits of exploration are defined less by experimental capacity and more by imagination itself.

This article was written by Konstantin Amm, Differential Bio.

No comments yet