Researchers are using artificial intelligence to develop better microorganism-led processes that efficiently devour products such as food waste, wastewater and animal manure to help boost the UK’s burgeoning green industry.

The project, which is led by the University of Surrey, has been awarded a £1.4 million grant by UK Research and Innovation.

The research will investigate the impact of using different types of waste to feed anaerobic digestors, along with computational tools for site-wide optimisation. Using sensors from across the value chain and information from sampling the microbes, the team will create virtual copies of the digestors (digital twins), which will enable AI systems to learn about the impacts of different feedstocks and early indicators of change.

Dynamic environment

Dr Michael Short, Principal Investigator from the University of Surrey’s School of Chemistry and Chemical Engineering and Fellow of the Institute for Sustainability, said: “The challenge of complex bioreactors are their lack of predictability, exacerbated by the dynamic environment within digestors – how does each species of microbe react to different food and to the other microbes around it? But the knowledge we’ll get from the data going through the digital twin digestor will start to address this uncertainty.”

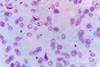

Anaerobic digestion is a natural process where microorganisms break down waste without oxygen. It’s used for waste management and fuel production. Microbes convert materials into soluble substances, which are then transformed into gases like methane. It’s used to treat waste, reduce landfill emissions, and generate renewable energy through biogas.

The UK’s 650 anaerobic digestors use microbes to consume waste, predominantly from agriculture and the food supply chain, capturing the greenhouse gases which are emitted as part of that process and purifying them to create a carbon-neutral substitute for natural gas. Creating home-grown biogas like this reduces the UK’s dependency on imported fuels and protects the country from the associated vulnerabilities.

Boosting biogas yields

Surrey’s project aims to increase biogas yields by 20% using the same inputs, simply through the benefits of more knowledge and better predictability of reactions.

Professor Jhuma Sadhukhan, also from the University of Surrey, who will focus on the environmental impact of all aspects of the anaerobic digestion process, said: “If digestors can start to reliably use a wider range of waste, there are multiple environmental benefits. For example, more waste can be turned into valuable forms of energy and transportation can be reduced.”

The University of Surrey is leading the project, which involves chemical process engineers, experts in microbial biology, AI researchers and people who assess the full environmental impact of processes. Future Biogas, a small anaerobic digestion company based at the University’s Surrey Research Park, will enable real-time monitoring in its reactors.

Increasing feedstock range

Denise Cysneiros, Head of Bioprocess and Optimisation at Future Biogas, said: “We hope this research will help us optimise the feedstock use in our anaerobic digestors and improve predictability of how the reactors will behave. It can also be a useful tool to improve flexibility and increase the range of feedstock we can use. This could mean lower greenhouse gas emissions and our costs reduced. We think there is an opportunity to boost our profitability.”

The funding is part of UKRI’s £13m investment in artificial intelligence research to enable the UK’s net zero target.

No comments yet