Bacterial spores – the hardy survival structures formed by certain bacterial species – are proving to be a game changer in the field of engineered living materials (ELMs).

These autonomously grown ELMs have a broad range of potential applications, such as detecting disease biomarkers and catalysing the breakdown of environmental pollutants. They might also function as self-healing composites. And ELMs could replace fossil-based materials, like plastics, in our daily life.

READ MORE: Biohybrids: Pioneering sustainable chemical synthesis at the energy-environment frontier

READ MORE: Scientists design protective ‘living tattoos’ for buildings

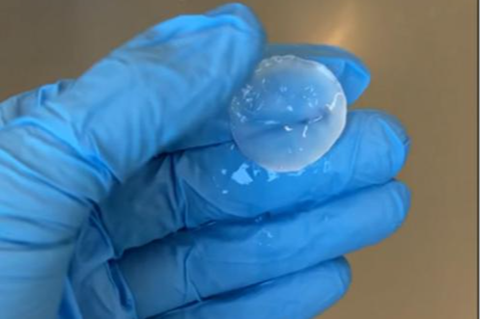

By embedding Bacillus spores within ELMs, Jeong-Joo Oh, Franka van der Linden, Marie-Eve Aubin-Tam and their fellow researchers from the University of Technology Delft (The Netherlands) have created living materials that not only endure harsh environments but can also be programmed to perform specific tasks. In the future, these materials may be a sustainable replacement for fossil-based materials. Their findings were published in Science Advances.

Inspiring bacterial life cycle

Unique to these new materials is their on-demand programmable functionality. The ELMs can sleep, survive harsh conditions, and awaken on command.

“Conventional living cells are able to perform useful functions like detecting biomarkers, but they only survive for a short time. We wanted a material we could use whenever we want to,” Oh says.

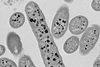

“So, we looked for a way to keep the cells alive and got inspired by the life cycle of bacteria.” Certain bacterial species can switch into a dormant and metabolically inactive state, called a spore. Spores are extremely resistant to heat, dryness, and chemical stress. “This dormant state allows us to ‘wake up’ the bacteria when the programmable functions are desired,” Oh says. “Using normal bacteria, you can only use the material within a few days or a week. We found out that with spores it still works after six months without losing functionality.”

Two species join forces

To fabricate the material, the scientists combined two bacterial species: Komogataeibacter rhaeticus and Bacillus subtilis.

K. rhaeticus produces strong bacterial cellulose fibers that act as a protective physical barrier. Bacillus contributes its spore-forming capacity. The mixture yields a robust living material.

By genetically modifying the bacterial spores’ surface, the team added the needed functionality. Also, the genetic engineering step enhanced the spores’ binding to the cellulose.

Next steps towards real-world use

Before these materials appear in our daily life, the ELMs’ performance and long-term stability should meet standards of existing materials.

“At this stage, our work is at a proof-of-concept-level in the laboratory,” Oh notes. “To use these materials in concrete, for instance, they should match the strength of existing building materials. But the results are already very promising. Step by step, I hope to replace unsustainable materials with living, self-sustaining ones.”

ELMs are innovative materials that use living cells to carry out their functions. The materials contain either natural or genetically engineered living cells. The cells are embedded in a supporting material made from natural or synthetic components. These materials can sense, respond, and even repair themselves, thanks to the biological activity of their embedded cells.

Topics

- Bacillus subtilis

- Bacteria

- bacterial nanocellulose

- bacterial spores

- Bioengineering

- Climate Action

- dormancy

- Economic Equality

- Engineered Living Materials

- Franka van der Linden

- Healthy Land

- Industrial Microbiology

- Innovation News

- Jeong-Joo Oh

- Komogataeibacter rhaeticus

- Marie-Eve Aubin-Tam

- UK & Rest of Europe

- University of Technology Delft

No comments yet