To see if a fish is fresh, people recommend looking at its eyes and gills or giving it a sniff. But a more accurate check for food quality and safety is to look for compounds that form when decomposition starts. Now, researchers reporting in ACS Sensors have developed a simple, effective electronic device that quickly measures one of these compounds. The prototype sensor can determine how fresh a fish is in less than two minutes.

For fish, signs of spoilage (cloudy eyes, bruised gills, foul or fishy odors) might take hours or even days to appear. In contrast, compounds such as hypoxanthine (HX) start forming almost immediately after death because nucleic acids and other molecules begin to break down. Therefore, researchers consider the level of HX a more reliable “freshness indicator” for both whole fish and individual fillets.

Currently, measuring HX requires time-consuming processes and specialized laboratory equipment. So, to make HX monitoring simpler and portable, Nicolas Voelcker, Azadeh Nilghaz, Muamer Dervisevic and colleagues created a microneedle-based freshness sensor. While microneedles are typically used in products for drug delivery or skincare, here they serve to boost the device’s sensitivity.

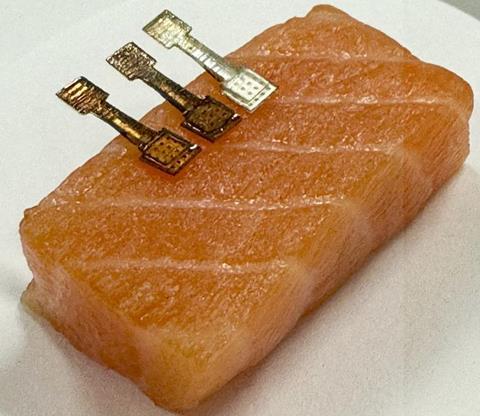

Microneedle array

To build the sensor, the team created a four-by-four microneedle array and coated it with specialized gold nanoparticles and an enzyme that breaks down HX. The sensor is pressed into the surface of a piece of fish and anchored by the microneedles. As the enzyme breaks down HX, the electric potential within the fish changes, and the sensor measures and interprets these changes.

The researchers validated the sensor’s performance with salmon steaks cut into small pieces and left to spoil for up to 48 hours at room temperature. The sensor detected concentrations of HX down to less than 500 parts per billion, which is a level consistent with fish samples considered to be “very fresh.” Results were returned in around 100 seconds.

READ MORE: Researchers develop novel sensor-integrated wrapper for food quality monitoring and preservation

Additionally, the new sensor’s sensitivity was comparable to that of a commercially available laboratory-based testing kit. Though further development is needed before the sensor will be available for use as a portable food safety tool, the researchers say that this demonstration shows its potential for real-time food-quality monitoring.

The authors acknowledge funding from the Australian Research Council Laureate Fellowship Scheme. They are in the process of filing a patent on this technology.

No comments yet