Heat‑resilient biofertilizers could help crops cope with rising temperatures but engineering them has been slow and uncertain. A new study at the National Institutes for Quantum Science and Technology (QST) shows that pairing experimental evolution with controlled gamma‑ray mutagenesis can accelerate the path to heat‑tolerant nitrogen‑fixing bacteria, shortening development timelines and opening practical routes to more reliable, climate‑ready microbial products for agriculture, food processing, pharmaceuticals, and biofuel production.

The study was made available online on November 19, 2025, and published in Volume 831 on July, 01, 2025, in the Mutation Research - Fundamental and Molecular Mechanisms of Mutagenesis journal.

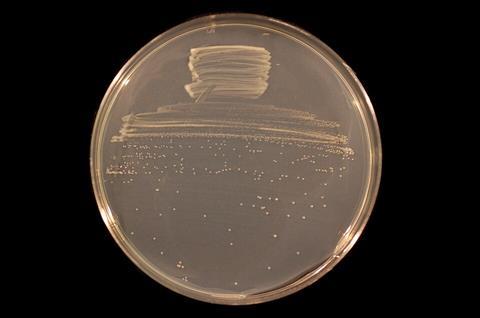

The team focused on Bradyrhizobium diazoefficiens USDA110, a workhorse bacterium used to help soybean and other legumes capture nitrogen. While the wild-type grows best at around 32–34 °C and stalls at ~36 °C, QST researchers raised culture temperatures stepwise from 34 °C to 37 °C over 76–83 days and irradiated populations ten times at specific doses, then selected the lines that continued to form robust colonies at 36 °C.

Sweet spot

A clear “sweet spot” emerged: around 40 Gy produced the greatest number of stable, heat‑tolerant lines, whereas higher doses (80–120 Gy) initially yielded more tolerant lines but with smaller colonies and traits that faded when selection relaxed, consistent with an excess of deleterious mutations. In practical terms, the method lets researchers tune the mutation load to favor beneficial changes while preserving overall fitness.

Genomic analyses of the top performers revealed changes in two core genes across independently evolved lines: the 16S rRNA gene, central to the protein‑making machinery, and rpoC, which encodes the β subunit of RNA polymerase. Convergent mutations in such essential systems point to mechanisms that help bacterial transcription and translation continue smoothly under heat stress—precisely the behaviors industry needs in high‑temperature processes.

“By combining adaptive laboratory evolution with precisely repeated doses of gamma rays, we shortened the path to robust, heat‑tolerant bacteria from months or years to just weeks,” said Dr. Yoshihiro Hase, project leader at the Takasaki Institute for Advanced Quantum Science (TIAQ), QST. “It’s a practical lever for making biofertilizers more reliable in hotter fields and bioreactors.”

Controllable mutagenesis

“This controllable mutagenesis avoids transgenic modifications and can be tuned to maximize beneficial changes while limiting genetic load,” added Dr. Katsuya Satoh, senior principal researcher at TIAQ. “We see a route that industry can adopt safely to boost resilience and productivity.”

Beyond agriculture, the approach could be generalized to yeasts, bacteria, and microalgae used in food processing, therapeutic manufacturing, and biofuel production—helping deliver high‑quality products at lower environmental cost. In the long term, QST anticipates ultra‑low‑cost microalgal cultivation and other heat‑tolerant platforms that contribute to food and energy security.

No comments yet