Systems metabolic engineering is a research field founded by Distinguished Professor Sang Yup Lee of KAIST to more effectively develop microbial cell factories, the core factor of the next-generation bio industry to replace the existing chemical industry that relies heavily on petroleum.

By applying a systemic metabolic engineering strategy, the researchers have developed a number of high-performance microbial cell factories that produce a variety of food and cosmetic compounds, including natural substances like heme and zinc protoporphyrin IX compounds which can improve the flavour and colour of synthetic meat; lycopene and β-carotene which are functional natural pigments that can be widely used in food and cosmetics; and methyl anthranilate, a grape-derived compound widely used to impart grape flavor in food and beverage manufacturing.

Kyeong Rok Choi, a research professor of the Bioprocess Research Center and Sang Yup Lee, a Distinguished Professor of the Department of Chemical and Biomolecular Engineering, have published a paper titled “Metabolic Engineering of Microorganisms for Food and Cosmetics Production” upon invitation by Nature Reviews Bioengineering to be published online by Nature after peer review.

Microbial cell factories

The research team covered cases of microbial cell factories that can produce amino acids, proteins, fats and fatty acids, vitamins, flavours, pigments, alcohols, functional compounds and other food additives used in various foods and cosmetics and the companies that have successfully commercialized these microbial-derived materials.

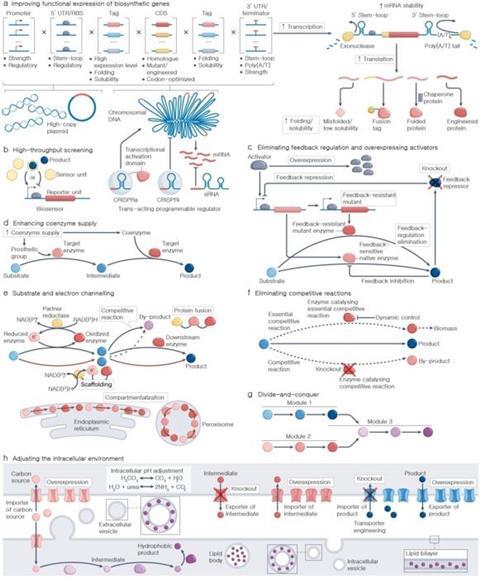

Furthermore, the paper organized and presents systems metabolic engineering strategies that can spur the development of industrial microbial cell factories that can produce more diverse food and cosmetic compounds in an eco-friendly way with economic feasibility.

For example, by producing proteins or amino acids with high nutritional value through non-edible biomass used as animal feed or fertilizer through the microbial fermentation process, it will contribute to the increase in production and stable supply of food around the world. Furthermore, by contributing to developing more viable alternative meat, further reducing dependence on animal protein, it can also contribute to reducing greenhouse gases and environmental pollution generated through livestock breeding or fish farming.

Eco-friendly flavours

In addition, vanillin or methyl anthranilate, which give off vanilla or grape flavour, are widely added to various foods, but natural products isolated and refined from plants are low in production and high in production cost, so in most cases, petrochemical substances derived from vanillin and methylanthranilic acid are added to food. These materials can also be produced through an eco-friendly and human-friendly method by borrowing the power of microorganisms.

Ethical and resource problems that arise in producing compounds like Calmin (cochineal pigment), a colouring added to various cosmetics and foods such as red lipstick and strawberry-flavoured milk, which must be extracted from cochineal insects that live only in certain cacti, and hyaluronic acid, which is widely consumed as a health supplement, but is only present in omega-3 fatty acids extracted from shark or fish livers, can also be resolved when they can be produced in an eco-friendly way using microorganisms.

Chocolate microbes

KAIST Research Professor Kyeong Rok Choi, the first author of this paper, said: “In addition to traditional fermented foods such as kimchi and yogurt, foods produced with the help of microorganisms like cocoa butter, a base ingredient for chocolate that can only be obtained from fermented cacao beans, and monosodium glutamate, a seasoning produced through microbial fermentation are already familiar to us.

“In the future, we will be able to acquire a wider variety of foods and cosmetics even more easily produced in an eco-friendly and sustainable way in our daily lives through microbial cell factories,” he added.

Distinguished Professor Sang Yup Lee said: “It is the mission of engineers to make the world a better place utilizing science and technology.

“Continuous advancement and active use of systems metabolic engineering will contribute greatly to easing and resolving the problems arising from both the food crisis and the climate change.”

No comments yet