Researchers in China have developed a novel, low-cost catalyst that efficiently removes antibiotic-resistant bacteria (ARB) from aquaculture wastewater, offering a potential new solution to one of today’s most pressing environmental and public health challenges.

The study, published in Biochar, reports on a bismuth ferrite (BiFeO₃, BFO) catalyst doped with peanut shell-derived biochar (BC). When combined with peroxymonosulfate (PMS), the biochar-doped composite rapidly inactivated ARB. In laboratory tests, the PMS/5% BC-BFO system removed nearly two orders of magnitude of ARB within just 10 minutes, achieving a reaction rate of 0.4401 min⁻¹.

READ MORE: Biochar and microbe synergy: a path to climate-smart farming

READ MORE: Fungi–biochar partnership boosts soil health and crop growth under cadmium stress

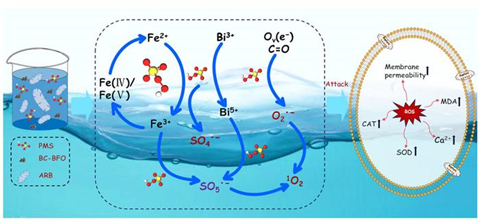

According to the research team, the superior performance of the 5% BC-BFO catalyst is attributed to its higher density of surface defects and oxygen vacancies, which serve as active sites for PMS activation. These sites generate reactive species such as sulfate radicals (SO₄•⁻), superoxide radicals (O₂•⁻), and singlet oxygen (¹O₂), as well as high-valent iron-oxo species. Together, these oxidants attack bacterial cell membranes, increase permeability, and trigger a cascade of oxidative stress that overwhelms bacterial defenses, leading to complete inactivation.

Critical reservoir

“Antibiotic resistance is a growing global threat, and aquaculture wastewater is a critical reservoir of resistant bacteria,” said co-corresponding author Dr. Muting Yan of South China Agricultural University. “Our peanut shell biochar-based catalyst not only removes these bacteria efficiently but is also inexpensive and easy to prepare, making it highly suitable for practical applications.”

Beyond high efficiency, the composite material demonstrated strong durability. After four reuse cycles, the 5% BC-BFO catalyst retained more than 60% of its initial ARB removal capacity, highlighting its potential for long-term wastewater treatment. The team also tested the system against various antibiotic-resistant E. coli strains carrying resistance genes, achieving significant inactivation within minutes.

Wastewater danger

Aquaculture, one of the fastest-growing food production sectors worldwide, heavily relies on antibiotics to prevent disease outbreaks. However, the release of untreated or inadequately treated wastewater contributes to the spread of ARB in natural ecosystems and increases the risk of human exposure through food and water. Traditional disinfection methods such as chlorination and UV irradiation often fail to fully remove resistant bacteria and may generate harmful byproducts. The new biochar–BiFeO₃ catalyst offers an alternative that combines effectiveness, environmental safety, and low cost.

“This study provides a new pathway for tackling antibiotic-resistant pollution in aquaculture wastewater,” added co-author Dr. Han Gong of The Hong Kong Polytechnic University. “By valorizing agricultural waste like peanut shells, we can create sustainable materials to protect both ecosystems and public health.”

Topics

- Antimicrobial Resistance

- Aquaculture

- Aquatic Microbiology

- Asia & Oceania

- Bacteria

- biochar

- bismuth ferrite

- Clean Water

- Disease in marine aquaculture

- Economic Equality

- Han Gong

- Innovation News

- Muting Yan

- One Health

- peroxymonosulfate

- South China Agricultural University

- The Hong Kong Polytechnic University

- Waste Management

- Wastewater & Sanitation

No comments yet