More than 90% of the commercially available carotenoids are synthetically produced using chemicals. To meet the increasing demand for cost-effective natural compounds in carotenoid synthesis, researchers at Xiamen University, China, have developed an engineered S. cerevisiae yeast strain capable of selectively overproducing carotenoids.

They redesigned the genomic sequence and critical pathways to optimize carotenoid production. This novel and successful research approach can be extended to other model microorganisms in the future.

Carotenoids, classified as tetraterpenoids, feature a carbon-hydrogen backbone and are found in algae, plants, and some microorganisms. The bright colors in most vegetables and fruits are a result of these carotenoid pigments. Due to their excellent antioxidant properties, carotenoids are widely used in healthcare, medicine, and cosmetics. In recent years, these antioxidant molecules have gained popularity as a nutraceutical food supplement.

Chemical synthesis

Most of the present-day, commercially available carotenoids are produced through chemical synthesis. The extraction and purification of carotenoids from natural sources is restricted by the costs and time-consuming nature of the processes involved. To circumvent these issues and meet the increasing demand for carotenoids, a group of researchers from China, led by Dr. Jifeng Yuan of Xiamen University, have successfully attempted to produce carotenoids by employing microbial synthesis techniques.

”Over the years, biotechnology has evolved drastically, allowing for specific modifications at the genetic level and regulating both, intracellular and intercellular dynamics. Our team has used multiple strategies on the model microorganism of Saccharomyces cerevisiae to improve the microbial synthesis of carotenoids,” says Dr. Yuan, sharing the inspiration behind using microbial synthesis technology.

Metabolic pathways

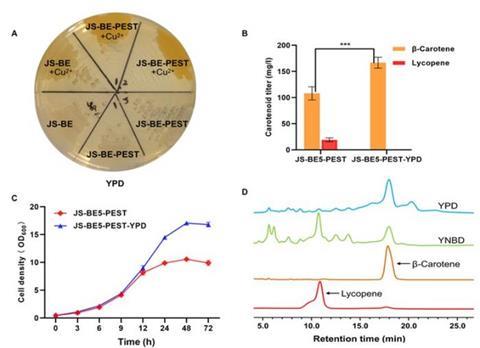

They initially reengineered the metabolic pathways in S. cerevisiae yeast to increase the overall content of acetyl-CoA, which can be easily converted into carotenoids. Further, they suppressed the secondary metabolic pathway of squalene synthase-ergosterol. This ergosterol pathway reduces the overall availability of energy and raw materials needed for carotenoid production. Also, as carotenoids are hydrophobic-resistant to water, their storage within yeast microorganisms was a challenge.

The researchers introduced the human lipid binding/transfer protein saposin B (hSapB) genetic sequence to enhance the storage of carotenoids. By changing the growth medium of yeasts to a low-cost, highly beneficial medium rich in yeast–peptone–dextrose and reengineering a genetic expression system, the output of biomass increased by 5-fold.

Beta-carotene

The S. cerevisiae yeast strain was selectively reengineered to optimize the production of high content of beta-carotene, a pre-cursor molecule of carotenoids. The results of this path-breaking research work were published online in the BioDesign Research journal on 10 January, 2024.

”We are very hopeful about the scalability and ease of implementing our novel carotenoid production technology and believe that in the near future such engineering strategies can be extended to other microorganisms as well,” concludes Dr. Yuan, highlighting the importance of the present research.

Advancing bio-engineering to create novel model microorganisms holds promise for future industrial carotenoid synthesis, facilitating the production of essential health supplements. This approach can significantly contribute to mitigating vitamin deficiencies and addressing malnutrition on a global scale.

No comments yet