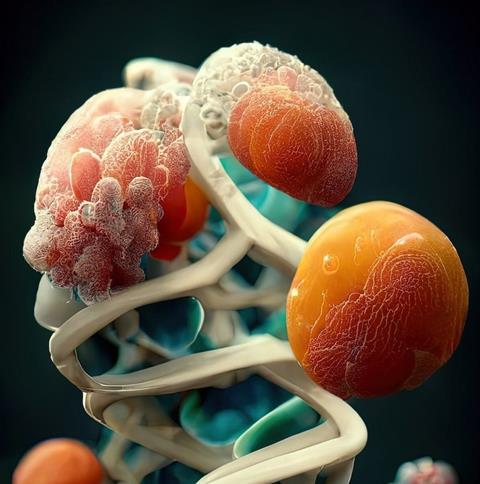

Recent advances in cell engineering and additive manufacturing have created exciting new opportunities for the production of Engineered Living Materials (ELMs), which can be made up entirely or in part of living cells.

By precisely organising different lineages of cells to create a hierarchical structure, ELMs can achieve multifunctional properties that rival and, in some cases, exceed those of natural living materials and traditional non-living materials. However, to unlock the full potential of living tissue manufacturing, significant hurdles must be overcome, such as achieving controlled printability at a viable scale and speed in the market. Only then can the true potential of ELMs be unleashed.

To bolster the field, the European Innovation Council has established a fund dedicated to Engineered Living Materials projects. In this context, the PRISM-LT project received a €2.3 million grant for a five-year programme that aims to create an adaptable platform for 3D bioprinting of living tissue with dynamic functionalities and predictable shapes.

Inspired by natural tissue development mechanisms, PRISM-LT will design heterogeneous 3D printable living materials that can build themselves into complex living tissues, including muscle-fat interfaces, at all relevant scales from sub-millimeter to centimeter.

Tunable bioink

To achieve this goal, PRISM-LT will create a novel tunable bioink that fosters a symbiotic relationship between stem cells and surrounding microorganisms, thus supporting stem cell differentiation toward a specific lineage.

The project will put its platform to the test by developing biomaterials for two primary applications. The first application involves creating organoids as in vitro models for preclinical research, which could aid in the discovery and testing of new drugs or therapies. The second application aims to engineer synthetic meat that closely mimics its natural counterpart, incorporating typical marbling, texture, nutritional values, and safety.

“Thanks to a multidisciplinary consortium PRISM-LT is a game-changer for bioprinting living materials. We tackle specific biomedical and food applications, but the platform is very flexible and has several applications,” explains Prof. Massimo Vassalli from the University of Glasgow and scientific coordinator of the PRISM-LT project and concept originator.

Indeed the project includes four universities (the University of Glasgow, Chalmers University of Technology, Radboud University, and the University of Aveiro), a non-profit company dedicated to innovation with social impact (IN society), and the 3D bioprinting company CELLINK, overall representing Italy, Portugal, Sweden, the Netherlands, and the United Kingdom.

Laura Martinelli, CEO of IN society and coordinator of the project, comments, “We are proud that the European Innovation Council has recognized our technology as a disruptive innovation for Engineered Living Materials. With PRISM-LT, the possibilities for ELMs are endless, and we are ready to usher in a new era of bioprinting.”

For more information, please visit the PRISM-LT project website: http://prism-livingtissues.eu/.

Topics

- 3D printing

- Bioengineering

- CELLINK

- Chalmers University of Technology

- Engineered Living Materials

- European Innovation Council

- Food Science & Technology

- Food Security

- Future Technologies

- Future Technologies

- IN society

- Industry News

- Laura Martinelli

- living tissue manufacturing

- Massimo Vassalli

- One Health

- organoids

- Pharmaceutical Microbiology

- PRISM-LT

- Radboud University

- synthetic meat

- UK & Rest of Europe

- University of Aveiro

- University of Glasgow

No comments yet