A common soil fungus may offer a sustainable solution to one of the world’s largest industrial waste problems while helping recover a critical nutrient for agriculture.

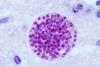

Researchers have shown that Aspergillus niger, a naturally occurring phosphate solubilizing fungus, can extract large amounts of residual phosphorus from phosphogypsum, a byproduct of phosphoric acid production that is generated in enormous quantities worldwide. The study demonstrates that more than 40 per cent of the phosphorus locked inside this waste material can be recovered through a biological process, offering a promising alternative to energy intensive chemical treatments.

READ MORE: Geoactive fungus mines rare earth elements from monazite ore

READ MORE: Fungal Transformation and Biorecovery of Minerals, Metals and Metalloids

Phosphogypsum is produced during the manufacture of phosphate fertilizers and is typically stored in large stacks that pose long term environmental risks. Globally, about 300 million tons are generated each year, while billions of tons have already accumulated. Although phosphogypsum contains roughly 1 percent phosphorus, most of it exists in insoluble forms that are difficult to reuse.

“Phosphogypsum has long been viewed as a liability, but it actually contains a valuable nutrient that is increasingly scarce,” said Zhen Li, the corresponding author of the study. “Our work shows that microorganisms can help transform this waste into a potential resource.”

Organic acids

In laboratory experiments, the research team incubated phosphogypsum with Aspergillus niger under controlled conditions. Over time, the fungus released organic acids, especially oxalic acid, which reacted with calcium in the waste material. This process reduced the tendency of calcium to bind phosphorus, allowing more phosphorus to dissolve into solution.

After 15 days of incubation, the bioextraction efficiency exceeded 40 percent, compared with only about 10 percent phosphorus release in systems without the fungus. Advanced imaging techniques revealed that much of the released phosphorus was absorbed directly into fungal cells, confirming active biological uptake rather than simple chemical dissolution.

“Our results show that the fungus is not just dissolving phosphorus, but actively using it for growth,” said Li. “This biological demand helps drive the extraction process forward.”

Microbial growth

The study also found that sulfate from phosphogypsum contributed to the synthesis of sulfur containing amino acids inside the fungal cells, further supporting microbial growth and sustained phosphorus release. Computer simulations confirmed that oxalic acid played a key role by binding calcium and preventing the reformation of insoluble phosphate minerals.

Phosphorus is an essential element for food production, yet global phosphate rock reserves are finite and increasingly costly to mine. At the same time, conventional phosphate fertilizers often suffer from low use efficiency and can contribute to water pollution.

“Recovering phosphorus from industrial waste aligns well with the goals of sustainable agriculture and circular resource use,” Li said. “This approach could reduce environmental risks while supplementing existing phosphorus supplies.”

Fungal bioextraction

While the experiments were conducted at the laboratory scale, the researchers believe the findings provide a strong foundation for future development. With further optimization, fungal bioextraction could be integrated into waste management systems or used to produce phosphorus enriched materials for agricultural applications.

The study highlights the untapped potential of microorganisms in addressing global environmental challenges. By harnessing natural biological processes, scientists are finding new ways to recover valuable resources from materials once considered useless waste.

The research was published online on January 19, 2026, in Environmental and Biogeochemical Processes, and involved collaboration among scientists specializing in environmental science, microbiology, and geochemistry.

No comments yet