Lignin is an abundant natural polymer which is eliminated as a byproduct in the pulp and paper industry. A recent review article explored different microbial processes available for sustainable lignin valorization, yielding not only environmental, but also economic benefits.

Researchers highlighted the current advancements as well as challenges faced while using naturally occurring and engineered microbes to transform depolymerized lignin into valuable high-value products.

The increasing focus on transitioning to a low-carbon society has driven research towards developing sustainable solutions. Lignin, a natural polymer that is abundantly found in plant biomass, is traditionally discarded as a byproduct in the pulp and paper industry or burnt as fuel. However, in recent times it has emerged as a valuable feedstock for producing various eco-friendly value-added products.

Two-stage strategy

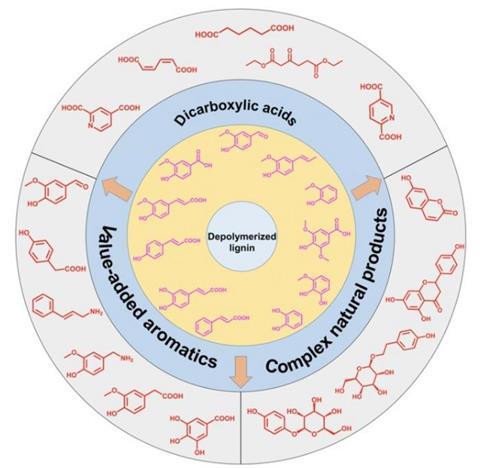

The most used lignin transformation method employs a two-stage strategy involving depolymerization followed by refining to transform lignin into beneficial products. Various pretreatment strategies and depolymerization techniques, including oxidative, reductive, and thermal depolymerization, and chemical modification, decompose lignin into lower weight phenolic compounds, which were then refined into specialized and high-value chemicals.

Moreover, lignin utilization can be maximized by using microbes capable of degrading lignin-derived aromatics into value-added products. Certain bacterial and fungal species such as Pseudomonas putida, Rhodococcus opacus, Rhodopseudomonas palustris, Phanerochaete chrysosporium, and Sphingomonas possess enzymes that enable them to directly utilize pretreated lignin or depolymerized aromatic compounds.

Additionally, the expression of heterologous enzymes in model microorganisms like Escherichia coli allowed the transformation of lignin-based platform compounds into more valuable end products.

Current progress

In a recent study, Professor Jianqiang Fan from the Technology Center, China Tobacco Fujian Industrial Co. Ltd. collaborated with Professor Zheyong Xue from Northeast Forestry University, Professor Anqi Chen from Jiangnan University, and Professor Jifeng Yuan from Xiamen University, to review the current progress in biological strategies for upcycling lignin using microbes.

Their study was published in Volume 6 of BioDesign Research on January 22, 2024. Elaborating on the purpose of their study, Professor Jifeng Yuan explains: “Furthermore, our review provides insights into the problems facing current biological lignin valorization while proposing further research directions to improve these technologies for the extensive accomplishment of the lignin upcycling.”

The article highlighted the promising production of dicarboxylic acids, particularly cis, cis-muconic acid (ccMA), from lignin. Traditional methods involved chemical synthesis from petroleum-based raw materials, but synthetic biology offered an eco-friendly alternative. Engineered strains of bacteria like P. putida, E. coli, and Amycolatopsis sp. were used to optimize the ccMA synthetic pathways, thereby synthesizing increased quantities ccMA from lignin-derived compounds. The researchers also discussed the use of engineered strains of P. putida and E. coli to synthesize adipic acid, a commercially important dicarboxylic acid, pyridine-dicarboxylic acids and beta-ketoadipate from lignin hydrolysates.

Microbial biocatalysis

The study further explained the use of microbial biocatalysis for synthesizing vanillin from lignin-derived ferulic acid and the effective production of gallic acid through microbial fermentation of lignin-derived compounds. The review also explored the improved biosynthesis of phenolic acids (like 4-hydroxyphenylacetic acid and 3,4-dihydroxyphenylacetic acid) and complex natural products including phenolic glycosides, coumarins, and flavonoids from lignin-derived compounds, using engineered microbial strains.

The researchers emphasized the simplicity and sustainability of direct processing of lignocellulosic hydrosylates by microbes into various molecules. They observed that lignin-degrading bacteria are widely distributed in natural lignin-rich diverse environments, and mainly belong to the phyla Proteobacteria, Actinobacteria, Firmicutes, and Archaea.

In conclusion, this study underscores the potential of harnessing microbes for sustainable lignin valorization, recognizing lignin’s potential as a renewable feedstock. The interdisciplinary approach aligns with global goals for a circular and sustainable bioeconomy, emphasizing the importance of microbiology, chemistry, synthetic biology, and genetic engineering in unlocking the full potential of lignin for high-value chemical production. A hopeful Professor Yuan concludes: “The effective use of lignin can drastically increase the cost-effectiveness of the lignocellulosic biorefinery, leading to a more sustainable and circular economy.”

Topics

- Agriculture

- Anqi Chen

- Asia & Oceania

- China Tobacco Fujian Industrial Co. Ltd.

- Climate Action

- Economic Equality

- Healthy Land

- Industrial Microbiology

- Jiangnan University

- Jianqiang Fan

- Jifeng Yuan

- lignin

- Nanjing Agricultural University

- Northeast Forestry University

- Phanerochaete chrysosporium

- Pseudomonas putida

- Research News

- Rhodococcus opacus

- Rhodopseudomonas palustris

- Soil & Plant Science

- Sphingomonas

- Synthetic Biology

- Waste Management

- Xiamen University

- Zheyong Xue

No comments yet