The term “pectinase” describes a group of enzymes that catalyze the hydrolysis, trans-elimination, and de-esterification processes necessary to decompose pectin molecules. Pectinases and their derivatives have been extensively used in the production of medicinal items, paper pulp, textiles, and fruit and vegetable products.

In plants and fruits, pectinase is a naturally occurring enzyme that helps fruits ripen; however, microbial sources are typically used in large-scale production. Pectinase is produced and widely distributed by fungi, bacteria, yeast, insects, worms, and protozoa. Due to their economic feasibility, microorganisms have been extensively used to produce enzymes on a commercial scale. For the large-scale synthesis of antibiotics, metabolites, and commercial enzymes since the 1940s, microorganisms were cultured in liquid broth while being constantly stirred. However, due to the limitations of submerged fermentation, commercial manufacturing began to move away from it. The production method based on solid-state fermentation is more productive, cost-effective, and ecologically friendly. It also has a high biomass yield, which improves the quality of the final product. There have been reports of acidic, neutral, and alkaline pectinases from different microbes.

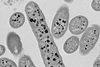

Microorganisms that can degrade pectin molecules include bacteria, fungi, and yeasts. Bacillus, Pseudomonas, Staphylococcus, Enterobacillus, and other bacterial species produce bacterial pectinases. Due to their longer shelf lives and greater catalytic efficiency, fungal pectinases frequently eclipse bacterial pectinases in importance. Aspergillus is a genus of filamentous fungi that has been proven to secrete 90% of its enzymes in the culture medium. Aspergillus is principally responsible for creating the most commercially advantageous pectinases, which are commonly used for the clarification of fruit juices. The fungi that are used most frequently for pectinase production include Aspergillus, Rhizopus, and Penicillium species. Aspergillus oryzae, Penicillium expansum, and Aspergillus niger are commonly regarded as safe for use in the food industry and fall under the unGRAS category by the US Food and Drug Administration. Other potential fungi for producing pectinase are Aspergillus niger, Aspergillus awamori, Trichoderma viride, Penicillium restrictum, Yarrowia lipolytica, and Mucor piriformis – indicating the broad range of potential for novel enzyme production.

Several microorganisms that produce pectinase use pectin as their carbon source. Pectin is a high molecular weight negatively charged heteropolysaccharide consisting of a main chain of (α,1–4) linked D-galacturonic acid monomers. The tensile strength and stiffness of plant tissue are provided by the naturally occurring pectin carbohydrate. Pectin is widely employed in the food industry as a gelling agent, thickener, or emulsifier. As a blood pressure stabilizer, cholesterol regulator, and detoxifier, it is also applicable in the pharmaceutical sector. Numerous bacteria that degrade pectins produce a large variety of compounds and enzymes that are employed in numerous industrial processes.

Natural sources of pectin include rice bran, wheat bran, malt sprouts, and the peels and cores of fruits like pomegranate, banana, lemon, orange, and pineapple. A significant amount of pectin with a high gelling grade is also present in fruits like mango (Mangifera indica), guava (Psidium guajava), banana (Musa sapientum), papaya (Carica papaya), and tomato (Lycopersicum esculentum). Two naturally occurring sources of pectin are apple pomace and citrus fruits, which both have 0.5–4% of the material in them. These are significant sources from which pectin can be extracted for use in industry.

Based on the pH range where they perform best, pectinases are categorized as either acidic or alkaline. Acidic pectinases are used in the winemaking and juice-processing industries to degrade pectic materials. Alkaline pectinases, on the other hand, are utilized in the creation of paper, the extraction of vegetable oils, the processing of textiles, the processing of tea and coffee, and even the treatment of wastewater. As we will see, the use of microbial pectinases may have a broad range of applications in the industry of the future.

Clothing

Plant fibers are separated from the stem by a process known as retting. Pectinase-mediated retting may be able to create clothing fibers that are softer, stronger, finer, and more uniform in length than fibers created using traditional retting methods, leading to better quality clothing. The controlled enzymatic degradation of pectins has been shown to make fibers more breakage resistant.

The pectinase-mediated degumming procedure benefits the environment since it slows down fiber deterioration without changing the characteristics of cellulosic fibers. The enzymatic dosage, degumming temperature, and degumming time for natural fibers should be optimized and monitored for optimum outcomes. Hemicellulose and lignin are stripped from the fiber surface to create single fibers, which could make the process easier for textile applications. Pectin or gum molecules contained in seed fibers can be dissolved by these enzymes, such as cellulases or pectinases. The fibers are typically soaked in water or a degumming solution before the microbial enzymes are added. After that, the enzymes’ impact on the gums allows for the easy removal of the fibers.

Pharmaceuticals

Pectic components are employed as medical adhesives for colostomy treatment. Pectins can be used in place of heparin to speed up the clotting process. For the treatment of iron deficient anemia, a combination of iron and pectin degradation is useful.

Pectin hydrogels act as “controlled agents” in colon cancer therapies. Pectin beads using an ionotropic gelation process are utilised for drug delivery systems. The inclusion of calcium pectinate gel beads in formulations or esterification of low-methoxy pectin both promote drug distribution. The primary mechanism of action of calcium pectinate is the development of insoluble hydrophilic coats that interact with one another in the host cell to promote the continuous release of particular drugs. Furthermore, a study that compacted the pectic substances made from orange and mango peels demonstrated the efficiency and controlled release of oral formulations. These exhibit remarkable binding properties when utilised in the formulation of various tablets and have a significant effect on functional polymers.

The emulsifying property of pectinases can also be used to encourage cell wall liquefaction in order to increase yields of essential oils. The oils extracted using enzymatic methods can maintain a high concentration of phyto compounds such as polyphenols, vital proteins, antioxidants, lipophilic bioactive compounds, and vitamin E while also enhancing storage stability.

Wastewater treatment

Pectin-containing wastewaters are a consequence of the processing of vegetables for food. Due to the low efficiency, high treatment costs, extended treatment periods, and complicated process of removing pectic compounds, their removal is challenging. In order to remove pectinaceous material more easily and to prepare wastewater for decomposition by activated sludge, microbial pectinolytic enzymes can be used as a pretreatment agent. These are treated in activated-sludge treatment columns using microbes. However, the pH changes hinder microbial activity and contribute to decreased treatment qualities. Pectinase-mediated enzymatic treatment enhances the speed of the process, lowers bacterial biofilm formations, and limits the growth of pathogenic fungi. Diverse techniques including physical dewatering, spray irrigation, chemical coagulation, direct activated sludge treatment, chemical hydrolysis followed by methane fermentation, and others, have been researched for the treatment of wastewater from citrus processing firms.

Biofuels

Approximately 50 million tonnes of pectin-rich waste are produced annually by the fruit processing industry, vegetable markets, and storage facilities. The garbage is deposited both on land and in water. The ability of these waste streams to biodegrade and ferment is advantageous for the biofuel production sector. Fruit wastes contain many sugars, including sucrose, fructose, and carbohydrates that can be recovered or recycled for the circular economy. Bioconversion of wastes with added value is a hot topic in research and is beneficial for creating high-quality bioethanol. In biorefineries, pectinases are also employed to hydrolyze the pectin found in pectin-rich agricultural and industrial waste. To enable the production of bioethanol or fermentation, these wastes are digested into simple sugars.

Food processing

Raw extracted juices are pulpy and heavy, which is mainly due to pectic compounds found in fruits. To lower the juice’s viscosity and turbidity, pectin, starch and protein complex colloids must be removed using a pectinase-mediated enzymatic process. These pulp colloids inhibit the speed of the filtration process and foul the membranes of the system. Pectinolytic treatment removes soluble pectin contributing to this unwanted hazy texture and forms gels or clumps in juice during storage. Juice becomes more transparent and has less viscosity when soluble pectin is removed.

The publishing sector

The production of paper and pulp mills utilises enzymatic intervention. The making of paper results in sheet formation from fibers, fragments of fibers, and inorganic filters like clay or CaCO3. Polysaccharides, which are problematic interfering compounds, are solubilized during the alkaline peroxide bleaching of pulps. Pectins are prominent among these polysaccharides. Catalytic demand, which refers to the capacity of polygalacturonic acid to bind cationic polymers, is highly influenced by the degree of polymerization. Galacturonic acid monomers, dimers, and trimers do not significantly increase cationic demand, however long chains and hexamers do. Pectinase can depolymerize galacturonic acid polymers, which reduces the cationic requirement of pectin solutions and the filtrate produced during peroxide bleaching.

The future

Pectinases represent an industrially important groups of enzymes with incredibly diverse applications having been documented so far. With the increasing demand for pectinases, there is a need to enhance their production and search for new applications. To significantly create or improve pectinolytic enzymes relevant to industrial products, new innovative methodologies are also now essential. The search for novel microbial sources using metagenomics, cloning of relevant pectinase genes and directed evolution are recent trends in research in microbial pectinases – a group of enzymes with the power to transform industrial processes.

No comments yet