Growing environmental concerns and the depletion of fossil resources have driven interest in greener routes for producing high-value chemicals. Microbial cell factories offer a promising alternative by using renewable feedstocks under mild conditions, but many industrial compounds are not naturally synthesized by microbes, and native pathways often lack sufficient metabolic flux.

Lauryl glucoside, a widely used non-ionic surfactant in cosmetics and personal care products, exemplifies this challenge, as it requires both a fatty alcohol precursor and a specialized glycosylation step absent in microorganisms. Overcoming these limitations demands the design of novel biosynthetic pathways that integrate enzymes from diverse biological sources within microbial hosts.

A study (DOI: 10.1016/j.bidere.2025.100045) published in BioDesign Research on 4 September 2025 by Pachara Sattayawat’s team, Chiang Mai University, demonstrates a sustainable microbial strategy for producing lauryl glucoside by engineering a non-natural biosynthetic pathway in Escherichia coli, revealing precursor availability as a key bottleneck and providing a foundation for replacing conventional chemical synthesis with greener biomanufacturing.

By reconstructing a non-natural metabolic route in Escherichia coli, the researchers demonstrated that simple sugars can be biologically converted into lauryl glucoside through the coordinated production of its fatty alcohol precursor and a final glycosylation step. The engineered strain achieved measurable lauryl glucoside titres and revealed substrate availability as a key bottleneck.

Stepwise strategy

The researchers first adopted a stepwise experimental strategy to evaluate precursor toxicity, optimize biosynthesis conditions, and then identify pathway bottlenecks for lauryl glucoside production in engineered Escherichia coli. They began by assessing the toxicity of 1-dodecanol, the key fatty alcohol precursor, by supplementing cultures with increasing concentrations (0–2.0 mM) in the presence or absence of a dodecane solvent overlay, while monitoring cell growth.

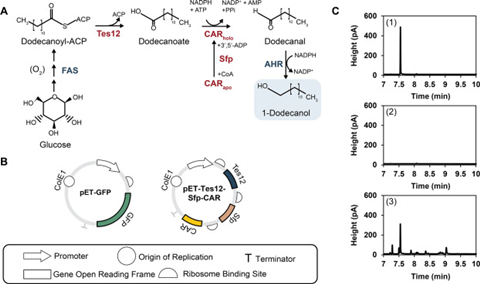

Next, they constructed an engineered strain expressing three heterologous enzymes (Tes12, Sfp, and CAR) to enable de novo 1-dodecanol biosynthesis and validated product formation using GC-FID. To enhance production efficiency, two optimization approaches were systematically tested: introducing a solvent overlay to reduce product volatility and tuning recombinant protein expression by varying IPTG induction levels.

Fermentation profiles, glucose consumption, and by-product formation were simultaneously analyzed to evaluate metabolic burden and carbon flux redistribution. Building on the optimized precursor supply, the team then introduced six different UDP-glycosyltransferases to catalyze the final O-glycosylation step toward lauryl glucoside formation, with product identity confirmed by HPLC and targeted LC-MS.

Pathway limitations

Finally, to pinpoint pathway limitations, precursor feeding experiments were performed by supplementing additional 1-dodecanol to drive metabolic flux toward the target product. The results showed that 1-dodecanol did not significantly inhibit E. coli growth under the tested conditions, enabling its use as a biosynthetic intermediate.

Solvent overlay increased 1-dodecanol titres by more than 40%, and optimal induction at 1.0 mM IPTG achieved the highest production (185.39 ± 3.62 mg/L) without impairing cell physiology, while acetate formation was reduced relative to control strains.

READ MORE: Biosurfactants for oil spill bioremediation

Among the tested glycosyltransferases, MtH2 exhibited the highest lauryl glucoside conversion efficiency, although titres remained low under endogenous precursor supply. Importantly, doubling the 1-dodecanol concentration led to up to an 18-fold increase in lauryl glucoside production, clearly identifying precursor availability as the dominant bottleneck and demonstrating effective redirection of carbon flux toward the desired surfactant.

Biodegradable surfactant

In conclusion, this work establishes a viable microbial platform for lauryl glucoside biosynthesis, demonstrating that engineered E. coli can convert renewable carbon sources into a high-value, biodegradable surfactant.

By identifying precursor availability as a central bottleneck and revealing opportunities for carbon flux redirection, the study lays a foundation for further pathway optimization and the sustainable biomanufacturing of glycolipid surfactants and related specialty chemicals.

Topics

- 1-dodecanol

- Asia & Oceania

- Bacteria

- Bioengineering

- bottleneck

- carbon flux

- Chiang Mai University

- Economic Equality

- Escherichia coli

- glycosyltransferases

- Healthy Land

- lauryl glucoside

- Microbial Fermentation

- Pachara Sattayawat

- Personal Care Product & Cosmetics

- precursors

- Strategies for Sustainability

- surfactants

- Sustainable Microbiology

- Synthetic Biology

No comments yet