South African based bio-pharmaceutical company Biovac has concluded a ground-breaking licensing and technology transfer agreement with the International Vaccine Institute (IVI), a non-profit international organisation headquartered in South Korea, for the manufacture of an oral cholera vaccine (OCV).

The project is significant for Biovac as it enables drug substance manufacturing capability to be built to produce the antigen/raw material needed to manufacture actual vaccines. This is one of the remaining steps in the vaccine manufacturing value chain that is currently missing not only at Biovac but across the African vaccine manufacturing landscape.

The agreement comes as cholera outbreaks – prompted by climate change, armed conflict and displacements – wreak havoc on fragile health systems, as observed in Pakistan, Nigeria and Malawi as recent examples. This places additional demand on already-limited supply of cholera vaccines globally. The extent of cholera outbreaks in recent years has escalated while there has been an increasing gap between supply and demand for cholera vaccines.

The partnership with IVI aims to license and transfer technology with the ultimate aim of increasing production volumes in order to reduce the critical shortage of vaccines needed to prevent cholera globally. This transfer of technology will also establish and demonstrate capacity for Good Manufacturing Process (GMP) scale-up, local manufacture of clinical trial product, and end-to-end production of vaccines in Africa for African and worldwide usage. After many decades, this will be a critical step forward for vaccine production on the continent.

This is in a market (Africa) where less than 1% of vaccines are locally manufactured and where infectious diseases are still the leading cause of death, especially in children under five years.

Notably, African leaders have committed to creating an indigenous vaccine industry, with the goal of boosting the share of vaccines manufactured in Africa from 1% in 2021 to 60% in 2040.

The agreement is underpinned by collective support of R120 million ($6.9 million) from Wellcome and the Bill & Melinda Gates Foundation for the first phase of the project. It will allow Biovac to expand its capabilities from filling and packaging of vaccine vials to end-to-end vaccine product development and drug substance manufacture.

Production capacity

Biovac CEO, Dr Morena Makhoana, says the COVID-19 pandemic exposed Africa’s lack of local production capacity.

“It became clear that increasing self-sufficiency is important if Africa is to have better control over its own public health and vaccine supply chains,” he said.

He says that for African vaccine manufacture to be sustainable, the continent needs to ensure that R&D, technology transfers, scale up, drug substance manufacture and licensing all take place on African soil, alongside already established fill-finish manufacturing activities.

“This initiative will be the beginning of end-to-end vaccine manufacture at Biovac, while at the same time addressing an ongoing and increasing cholera disease burden globally. In addition, this feeds directly into Biovac’s facilities expansion plan to scale up production capacity and will most likely be the first product (drug substance and drug product) to be manufactured in our new facility when it comes on line.”

The technology transfer process will commence in January 2023, with the first clinical trial batches expected to be produced in 2024 and licensing of the product by the South African National Regulatory Authority (SAHPRA) to be concluded in 2026 alongside WHO Prequalification certification which will follow shortly thereafter

Makhoana highlights the importance of achieving pre-qualification from the World Health Organization (WHO). “Through this and other projects, Biovac plans to attain WHO pre-qualification. We will then be well placed to supply UN agencies such as WHO and UNICEF/GAVI as many African countries and other least developed countries source their vaccines through this mechanism.

Technical know-how

Director of IVI’s Cholera Program, Dr Julia Lynch, says IVI’s technical know-how and required materials to produce OCV have been transferred to four different manufacturers to date.

“OCV is a proven, highly effective preventive measure against a disease that strikes the most vulnerable. Enthusiastic uptake of the vaccine by countries has resulted in a demand that exceeds current supply, and the supply shortage has been made worse amid an increasing number of cholera outbreaks in 2022.

“We are thrilled to partner with Biovac to complete a technology transfer of OCV that will add another manufacturer to the marketplace and expand production capacity. With Biovac and the support of the Gates Foundation and Wellcome, we aim to expand the global supply of OCV and prevent cholera worldwide.”

IVI Director-General, Jerome Kim, says maintaining a global supply of the cholera vaccine is critical for preventing cholera and controlling outbreaks. “In the face of a supply shortage, IVI’s collaboration with Biovac to complete the transfer of OCV technology will make a significant impact on our ability to protect communities at highest risk of this deadly, although vaccine-preventable, disease.”

President of the Bill & Melinda Gates Foundation’s Global Health Program, Trevor Mundel, says the foundation is excited to support this important project to increase access to lifesaving oral cholera vaccines.

“Unfortunately, we are seeing now more than ever that it will be essential to have a robust and diverse supply of the vaccine to prevent death and disability from this persistent scourge. We see this type of tech transfer to manufacturing partners as a key way to ensure a strong supply of high-quality, affordable vaccines.”

Professor Gordon Dougan, Director of Infectious Diseases at Wellcome Trust, says the tools needed to control cholera exist – a combination of good epidemiology, water management and vaccines – but now we urgently need to increase access to an affordable, effective vaccine to meet the growing demand.

“We are proud to be funding this project to build capacity to manufacture this much-needed vaccine and generate a sustainable vaccine supply within the countries that need them most. For the first time in recent history, an affordable life-saving oral cholera vaccine will be made on the African continent, for the African people,” concludes Dougan.

South African based Bio-pharmaceutical company, Biovac, has concluded a ground-breaking licensing and technology transfer agreement with the International Vaccine Institute (IVI), a non-profit international organisation headquartered in South Korea, for the manufacture of an oral cholera vaccine (OCV).

The project is significant for Biovac as it enables drug substance manufacturing capability to be built, that is, production of the antigen/raw material needed to manufacture actual vaccines. This is one of the remaining steps in the vaccine manufacturing value chain that is currently missing not only at Biovac but across the African vaccine manufacturing landscape.

The agreement comes at a time as cholera outbreaks – prompted by climate change, armed conflict and displacements – wreak havoc on fragile health systems, as observed in Pakistan, Nigeria and Malawi as recent examples. This places additional demand on already-limited supply of cholera vaccines globally.[1] The extent of cholera outbreaks in recent years has escalated while there has been an increasing gap between supply and demand for cholera vaccines.

The partnership with IVI aims to license and transfer technology with the ultimate aim of increasing production volumes in order to reduce the critical shortage of vaccines needed to prevent cholera globally. This transfer of technology[2] will also establish and demonstrate capacity for Good Manufacturing Process (GMP) scale-up, local manufacture of clinical trial product, and end-to-end production of vaccines in Africa for African and worldwide usage. After many decades, this will be a critical step forward for vaccine production on the continent.

This is in a market (Africa) where less than 1% of vaccines are locally manufactured and where infectious diseases are still the leading cause of death, especially in children under five years.[3]

Notably, African leaders have committed to creating an indigenous vaccine industry, with the goal of boosting the share of vaccines manufactured in Africa from 1% in 2021 to 60% in 2040.[4]

The agreement is underpinned by collective support of R120 million ($6.9 million) from Wellcome and the Bill & Melinda Gates Foundation for the first phase of the project. It will allow Biovac to expand its capabilities from filling and packaging of vaccine vials to end-to-end vaccine product development and drug substance manufacture.

Biovac CEO, Dr Morena Makhoana, says the COVID-19 pandemic exposed Africa’s lack of local production capacity. “It became clear that increasing self-sufficiency is important if Africa is to have better control over its own public health and vaccine supply chains.” He says for African vaccine manufacture to be sustainable, the continent needs to ensure that R&D, technology transfers, scale up, drug substance manufacture and licensing all take place on African soil, alongside already established fill-finish manufacturing activities.

“This initiative will be the beginning of end-to-end vaccine manufacture at Biovac, while at the same time addressing an ongoing and increasing cholera disease burden globally. In addition, this feeds directly into Biovac’s facilities expansion plan to scale up production capacity and will most likely be the first product (drug substance and drug product) to be manufactured in our new facility when it comes on line.”

The technology transfer process will commence in January 2023, with the first clinical trial batches expected to be produced in 2024 and licensing of the product by the South African National Regulatory Authority (SAHPRA) to be concluded in 2026 alongside WHO Prequalification certification which will follow shortly thereafter

Makhoana highlights the importance of achieving pre-qualification from the World Health Organization (WHO). “Through this and other projects, Biovac plans to attain WHO pre-qualification. We will then be well placed to supply UN agencies such as WHO and UNICEF/GAVI as many African countries and other least developed countries source their vaccines through this mechanism.

Director of IVI’s Cholera Program, Dr Julia Lynch, says IVI’s technical know-how and required materials to produce OCV have been transferred to four different manufacturers to date.

“OCV is a proven, highly effective preventive measure against a disease that strikes the most vulnerable. Enthusiastic uptake of the vaccine by countries has resulted in a demand that exceeds current supply, and the supply shortage has been made worse amid an increasing number of cholera outbreaks in 2022.

“We are thrilled to partner with Biovac to complete a technology transfer of OCV that will add another manufacturer to the marketplace and expand production capacity. With Biovac and the support of the Gates Foundation and Wellcome, we aim to expand the global supply of OCV and prevent cholera worldwide.”

IVI Director-General, Jerome Kim, concurs with Lynch and says maintaining a global supply of the cholera vaccine is critical for preventing cholera and controlling outbreaks. “In the face of a supply shortage, IVI’s collaboration with Biovac to complete the transfer of OCV technology will make a significant impact on our ability to protect communities at highest risk of this deadly, although vaccine-preventable, disease.”

President of the Bill & Melinda Gates Foundation’s Global Health Program, Trevor Mundel, says the foundation is excited to support this important project to increase access to lifesaving oral cholera vaccines.

“Unfortunately, we are seeing now more than ever that it will be essential to have a robust and diverse supply of the vaccine to prevent death and disability from this persistent scourge. We see this type of tech transfer to manufacturing partners as a key way to ensure a strong supply of high-quality, affordable vaccines.”

Professor Gordon Dougan, Director of Infectious Diseases at Wellcome Trust, says the tools needed to control cholera exist – a combination of good epidemiology, water management and vaccines – but now we urgently need to increase access to an affordable, effective vaccine to meet the growing demand.

“We are proud to be funding this project to build capacity to manufacture this much-needed vaccine and generate a sustainable vaccine supply within the countries that need them most. For the first time in recent history, an affordable life-saving oral cholera vaccine will be made on the African continent, for the African people,” concludes Dougan.

Topics

- Asia & Oceania

- Bill & Melinda Gates Foundation

- Biovac

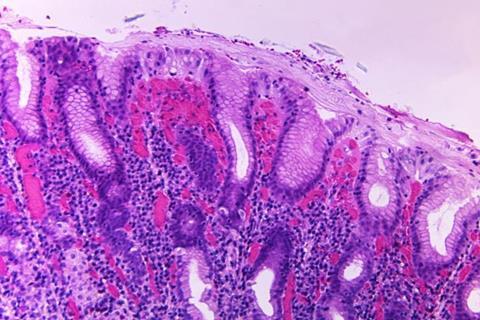

- cholera

- Clean Water

- Disease Treatment & Prevention

- Dr Julia Lynch

- Dr Morena Makhoana

- Economic Equality

- Gates Foundation

- Industry News

- Infection Prevention & Control

- Infectious Disease

- International Vaccine Institute

- IVI

- Middle East & Africa

- OCV

- One Health

- Professor Gordon Dougan

- South Africa

- South African National Regulatory Authority

- Trevor Mundel

- Vaccinology

- Wellcome

- World Health Organization

No comments yet