Scientists have developed a way to synthesize medicarpin in yeast. Like palitaxel in the 1990s, this tumor-attacking sustance has only limited natural quantitites and is considered difficult to synthesize. Developing an efficient biosynthesis method, therefore, is a key step in making the production of this antitumor and antibacterial isoflavonoid efficient and sustainable.

While the Fabaceae plant family from which medicarpin is extracted is quite common and includes peas, alfalfa, acacia, and carob, the substance is in relatively low quantities within those plants. Furthermore, crops are susceptible to climate fluctuations and land use restrictions. Chemical synthesis is still a multi-step process beset by high production costs and environmental pollution concerns.

With a ready supply, medicarpin could become more widely used in the treatment of osteoporosis, inflammatory disease, and other indications.

READ MORE: Engineered yeast delivers record levels of animal-free chondroitin sulfate

As senior author Yongjun Wei, Chengwei Li, and colleagues at Zhengzhou University, the University of Nottingham, and Henan University of Technology, point out in a recent paper, “The biosynthesis of medicarpin in S. cerevisiae involves the coordination of multiple interconnected metabolic pathways, including glycolysis, the pentose phosphate pathway (PPP), the shikimate pathway, and the isoflavonoid biosynthesis pathway.”

“Synthetic biology and microbial biomanufacturing represent a powerful, third paradigm for producing complex natural productions,” Wei tells GEN. “This platform has the potential to provide a reliable, scalable, environmentally friendly source of bioactive compounds…potentially overcoming supply chain and sustainability challenges associated with conventional methods.”

Yeast strains

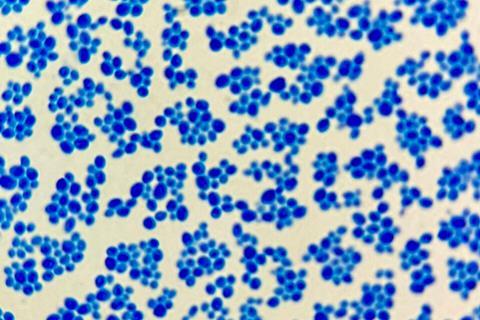

The team’s success hinged upon developing yeast strains adept at flavonoid synthesis. Ultimately, they engineered 26 strains of S. cerevisiae, overexpressing and mutating endogenous yeast genes that were vital for flavonoid synthesis, and creating a downstream flavonoid biosynthetic pathway in engineered yeasts.

Medicarpin production peaked at more than 157 μg/L in the GlaN26 strain. Optimization involved organelle engineering to knock out or knock down genes in competing pathways or with inhibitory transcription factors that would affect the targeted metabolic pathways, Wei, Li, and colleagues report.

Engineered S. cerevisiae has been used previously to generate a variety of natural products, such as cycloastragenol, which activates telomerase and has been associated with telomer elongation.

Small quantities

This method currently produces relatively small quantities of medicarpin, however. “The current titers remain orders of magnitude below commercially viable levels,” Wei says, and significant improvements in production efficiency and yield are essential before scale-up is feasible.

“Our primary challenge lies in advancing the technology from a laboratory proof-of-concept to a robust industrial process,” Wei adds. “Further genetic and metabolic engineering of the yeast strains to drastically improve titer, yield, and rate under scaled fermentation conditions is necessary.”

Topics

- Antimicrobials

- Asia & Oceania

- Bacteria

- Bioengineering

- Cancer Microbiology

- Chengwei Li

- Economic Equality

- Fabaceae

- Fungi

- Henan University of Technology

- Industrial Microbiology

- medicarpin

- One Health

- Pharmaceutical Microbiology

- Research News

- Saccharomyces cerevisiae

- Synthetic Biology

- University of Nottingham

- Yongjun Wei

- Zhengzhou University

No comments yet